Frimaq

Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine

Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine

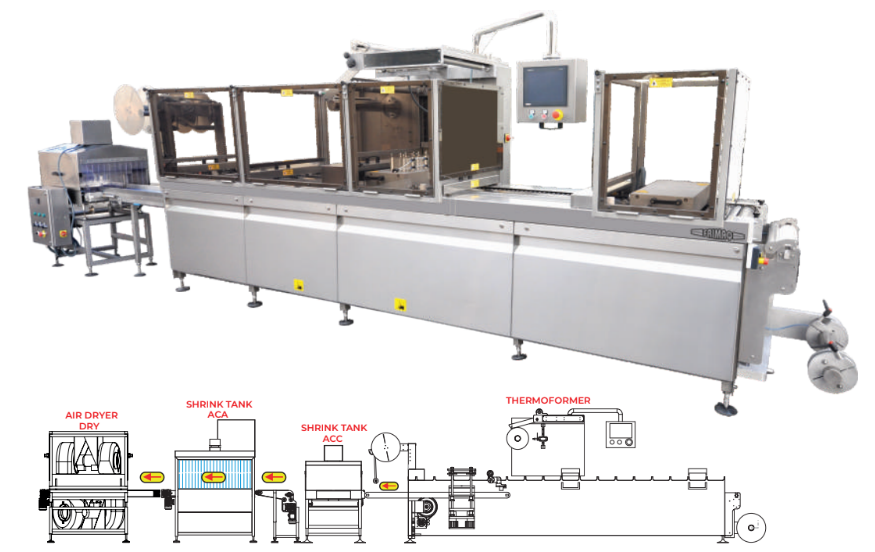

Introducing the Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine - the ultimate solution for automated horizontal packaging. This state-of-the-art machine revolutionizes the packaging process by seamlessly integrating two film reels, allowing you to select the perfect material to suit your specific packaging needs. Whether you're in the food industry or any other sector, our thermoforming machines are designed to cater to your unique requirements, ensuring a customized packaging process tailored to your products.

The Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine boasts incredible versatility, making it indispensable across a wide range of industries. From pharmaceutical companies to non-food and food manufacturers, this machine caters to diverse technological applications with its array of available models, capable of meeting various demands.

The procedure of the Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine is as follows: First, the powerful radiators efficiently heat the sheet, softening it for the subsequent thermoforming process. The thermoforming can be accomplished through different methods, such as vacuum, pressure, or mechanical deformation of the sheet. Additionally, it can be classified based on the mold cavity method, whether positive or negative. Once the thermoforming is complete, the containers are filled with the product, and the sealing process ensues. Finally, the containers are expertly cut into individual pieces using precise knives, completing the thermoforming process.

Investing in the Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine brings with it a multitude of advantages. It is a highly effective solution for both large-scale and small-scale production runs. The machine supports a wide range of materials, including PAI, PET, ABS, PVC, polycarbonate, and acrylic, providing flexibility in packaging options. The molds utilized are cost-effective, ensuring swift manufacturing periods. The technique is well-suited for prototyping and bulk manufacturing, resulting in minimal service costs. Furthermore, the machine offers economic advantages in terms of color customization and response time. In certain cases, it can even replace the traditional injection procedure. Above all, the Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine delivers exceptional, high-quality results that can be tailored to meet the specific demands of any client.

To ensure the highest standards of safety, the Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine incorporates safety protections in compliance with CE standards. Your peace of mind is our top priority.

RAM Manufacturing Equipment, located in Corona, California, is your trusted partner for all your packaging needs. We offer comprehensive services, including training, installation, and ongoing support for the Frimaq Model TFF (Flexible) Thermoformer Automatic Packaging Machine, as well as a wide range of other cutting-edge machines. Contact us today or visit our facility for more information. Experience the future of packaging technology with RAM Manufacturing Equipment.

Couldn't load pickup availability

Materials

Materials

Dimensions

Dimensions

Shipping & Returns

Shipping & Returns

-

Industry's Best Customer Service

Call our friendly and knowledgeable team to make sure you're getting the right item for the job. Our team has decades of food processing experience and is looking forward to hearing from you! 951-734-8152 or email us at support@rameqpt.com

-

Fast Shipping

We stock many of our items at our main facility in Corona, CA. Other items are ship form our 14 Strategically located distribution centers nationwide and internationally. Equipment is usually made to order and lead times vary. Contact us today for current equipment lead times. 951-734-8152.